Installing rope on your cable winch in 2026 demands meticulous attention. It requires careful selection, precise preparation, and correct attachment for safe and efficient operation. Proper tensioned spooling is also vital. This guide details each crucial step, ensuring optimal performance from your equipment, including any MARSHINE cable pulling winch.

Choosing the right rope for your cable winch is a critical step. You will decide between synthetic and wire rope. Synthetic rope can last up to 10 years with light use; heavy use requires replacement every one to two years. UHMWPE rope, a synthetic type, extends its lifespan by 42% due to low stretch and UV-resistant fibers. Wire rope's working life depends heavily on proper maintenance and safe storage. MARSHINE emphasizes selecting the right material for optimal performance.

Matching your rope's diameter and length to your cable winch is crucial for safety and efficiency. Incorrect rope length significantly impacts performance. If the rope is too thin, its capacity falters. A rope that is too thick will not spool correctly. An undersized rope increases overload risk. Thicker lines engage the drum better but need a compatible spool size. If the rope is too thin or stretchy, it can slip, wasting power. Under heavy loads, an incorrect rope can snap, causing dangerous recoil. For matching rope diameter to winch capacity, use a safety factor of 1.5:1 to 2:1. This means the winch line's breaking strength should be 1.5 to 2 times the winch's pulling power. For example, a 9,000 lb winch needs a line with a breaking strength between 13,500 and 18,000 lbs or higher. The rope's length must cover the trailer's ramp distance plus slack, typically 25 to 50 feet.

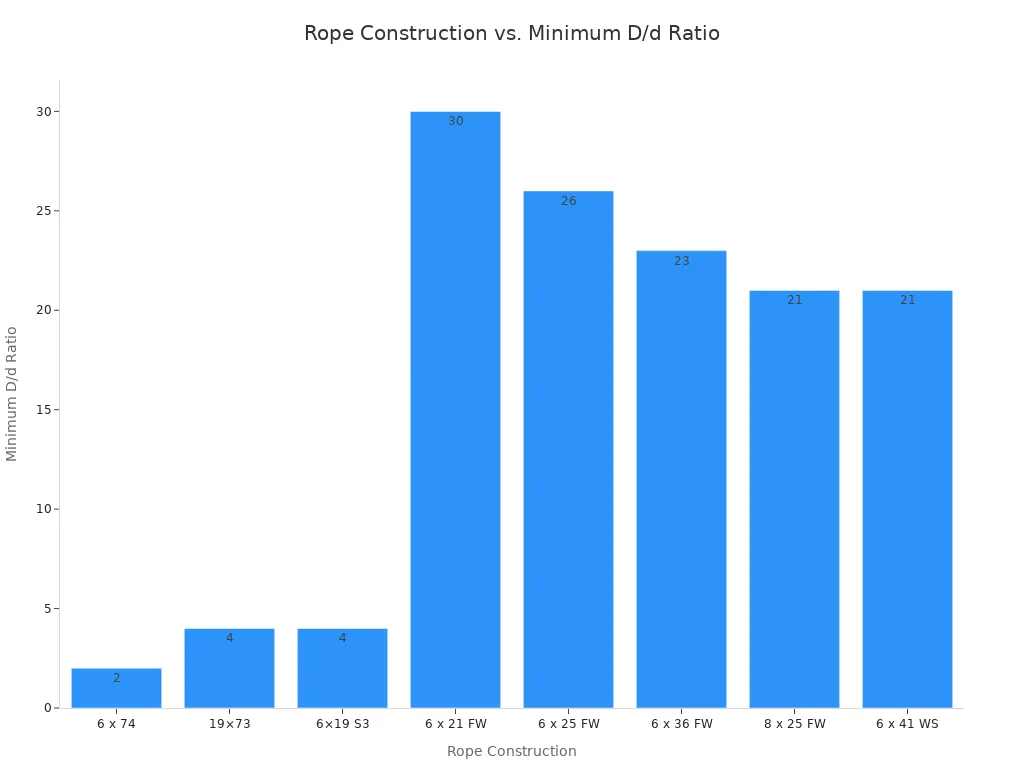

Here's a guide for minimum D/d ratios for various rope constructions:

| Rope Construction | Minimum D/d Ratio |

|---|---|

| 6 x 74 | 2 |

| 19×73 | 4 |

| 6×19 S3 | 4 |

| 6 x 21 FW | 30 |

| 6 x 25 FW | 26 |

| 6 x 36 FW | 23 |

| 8 x 25 FW | 21 |

| 6 x 41 WS | 21 |

Rope material properties greatly influence durability and safety. Polyurethane coatings resist water, dirt, and abrasion, extending lifespan. Heat-coated urethane binds fibers, making rope tougher and more flexible. Sleeves and PVC layers protect against sharp rocks. Glue impregnation stabilizes the core, preventing internal wear. UV stabilizers decrease sun degradation. Synthetic ropes are lighter than steel, easier to handle, and reduce vehicle weight. If synthetic rope breaks, it recoils with less force, reducing injury risk. They float on water and are more flexible for spooling. Dyneema and Spectra are common high-strength fibers, offering excellent strength-to-weight ratios and resistance to abrasion and UV light.

Always inspect any new rope thoroughly for defects before installing it on your cable winch. Look for kinks, frays, cuts, or any shipping damage. Even minor imperfections compromise the rope's integrity and safety. A careful inspection ensures your rope performs reliably, aligning with MARSHINE's commitment to safe and easy-handle products.

Properly mounting your cable winch is the first critical step. It ensures safety and reliable operation. You must confirm the structural soundness of the mounting surface before you begin installation. Always use Grade 8 or higher-rated hardware. Tighten all connections to the correct torque specifications. This prevents loosening from vibrations during use.

For electric winches, ensure all electrical connections are clean, tight, and protected from the elements. The battery must be healthy, with high Cold Cranking Amps (CCA) and Reserve Capacity (RC). Consider upgrading to an AGM battery or a dual-battery system if you use the winch frequently. The alternator also needs to be in good condition. Route power cables carefully. Avoid sharp edges, heat sources, and moving parts. Secure the cables firmly with zip ties or clamps. The path should be as short and direct as possible to minimize voltage drop.

Install the correct type of fairlead. Use a roller fairlead for steel wire rope and an aluminum hawse for synthetic rope. This guides the winch line smoothly onto the drum. Ensure the fairlead mounts with high-grade hardware and has no sharp edges. Mount the winch so the line pulls straight out from the fairlead. It should be perpendicular to the drum. The winch must sit perfectly flat against the mounting surface. This prevents uneven spooling and mechanical failure. Finally, apply medium-strength (blue) thread-locking compound on bolt threads. This stops them from loosening due to vibration. MARSHINE winches are designed for secure mounting, providing a stable base for all your pulling needs.

Before attaching any rope, you must clean the cable winch drum thoroughly. Dirt, debris, or old lubricant can cause uneven spooling and damage the new rope. Use a clean cloth to wipe down the drum surface. Check for any signs of rust, corrosion, or sharp edges that could fray the rope. Inspect other components like the fairlead and the drum anchor point. Make sure they are free from damage and operate smoothly. A clean drum helps the rope lay evenly and extends its lifespan.

Safety is paramount when working with a cable winch. Always wear appropriate personal protective equipment (PPE). This includes heavy work gloves to protect your hands. Eye protection, such as goggles, shields your eyes from debris. A hard hat may be necessary depending on your work environment. Sturdy boots also provide foot protection.

Before you start, ensure your work area is clear of obstructions. Read your winch's instruction manual carefully. Disconnect power to the winch if it is electric. This prevents accidental activation. Never work under a suspended load. Always maintain a safe distance from the winch line when it is under tension.

Attaching the rope correctly to the drum anchor point is crucial for the winch's performance. The method varies slightly depending on whether you use synthetic or steel rope.

For synthetic lines:

For steel cables:

MARSHINE designs its cable winches with user-friendly anchor points. This makes the attachment process straightforward and secure.

The choice between synthetic rope and steel cable affects the attachment method and overall winch performance. Each material has distinct advantages and disadvantages.

Synthetic rope is lightweight and flexible. It does not store energy, making it safer if it breaks. It floats in water and resists rust. Synthetic rope is also stronger than steel cable and can be spliced in the field. However, it is not UV stable and requires protection. It can melt and is subject to internal fraying from dirt or sand. Synthetic rope is also not as abrasion-resistant as steel and can be harder to visually inspect for damage. It is generally more expensive and can retain water or freeze.

Steel cable is very durable and long-lasting. It can drag over rough terrain like rocks. It is UV stable and abrasion-resistant. Steel cable is also less expensive than synthetic rope. However, it is heavy and stores significant energy under load, posing a safety risk if it breaks. It does not float and is less flexible. Steel cable tends to kink and can develop frays or burrs, which cause splinters. It is difficult to fix in the field and can rust if not maintained.

Your application dictates the best attachment method and rope type. MARSHINE offers a range of cable winch solutions. They support both synthetic and steel rope, ensuring you have the right tools for any job.

Maintaining proper tension when spooling rope onto your cable winch is extremely important. It ensures the rope wraps tightly and neatly on the drum. This tight fit prevents many problems. For example, lower rope layers cannot pull through. Insufficient tension can cause several issues. The rope can crush itself. It might also jump the sheave.

Synthetic rope is quite slippery. It will slide around on the drum if you apply tension without proper initial spooling. It tries to fill any empty spaces. When the line gets loaded, its diameter shrinks. This creates gaps between the wraps. Later wraps can then fall into these gaps. This leads to uneven spooling.

Insufficient friction can cause the winch rope to slip. This leads to excessive twisting. Such twisting damages the rope's internal structure. It can even cause breakage. Also, increased friction and wear happen between the rope and the drum. This leads to premature wear and breakage. This is especially true if the rope crosses or overlaps. Uneven tension during spooling or an improperly installed drum can also hurt the rope's mechanical properties. This makes breakage under tension more likely.

To achieve proper tension, follow these steps:

Here are some recommended initial winding tensions:

| Rope Type | Initial Winding Tension (First Layer) | Minimum Wraps on Drum |

|---|---|---|

| General Winch Lines | Approximately 50 pounds | 4 |

| AmSteel®-Blue | Approximately 50 pounds | 8 |

Guiding the rope evenly across the cable winch drum is key for its longevity and performance. Always spool the rope "under-wound." This means it comes from the bottom of the drum. This method matches the rope's natural lay. It also minimizes side-load and stops the rope from digging into the drum's flange.

Apply consistent tension. After the first few wraps, pull with about 1,000 lb (≈ 454 kg). The initial wraps should have tension at 2% of the rope's breaking strength. This sets the rope's memory. It also prevents loose layers. Each new wrap should sit right next to the one before it. Avoid overlaps, gaps, or kinks. If a kink forms, stop and fix it. Periodically run a finger along the drum edge. This helps you correct any misalignment before it gets worse.

A well-designed winch cable drum protects the rope. It prevents abrasion and limits side-load. It also keeps the line aligned with the fairlead. Look for deep, V-shaped groove profiles. These securely capture the rope. Wide flanges prevent crushing. A highly polished bearing surface reduces friction. Ensure the fairlead aligns perfectly with the drum's centerline. Incorrect alignment can cause reverse bending. This creates concentrated stress points and damages the rope.

After installing the rope, perform a test run on your cable winch. This step confirms everything works correctly and safely. First, ensure the winch is securely mounted. Check all connections one last time. Then, find a safe, open area. Attach the winch hook to a secure anchor point. This could be a sturdy tree or another vehicle.

Slowly extend the rope. Watch how it spools off the drum. Look for any signs of binding or uneven unwinding. Then, slowly retract the rope. Observe how it spools back onto the drum. It should lay evenly and tightly. Listen for any unusual noises from the winch motor or gears. Check for any excessive heat. If you notice any issues, stop immediately. Investigate the problem before continuing. A successful test run gives you confidence in your setup. It also ensures the winch is ready for real-world tasks. MARSHINE winches are built for reliability, and a test run helps confirm their optimal performance.

Regular maintenance extends the life of your cable winch rope. It also ensures safe operation. After each use, inspect the entire length of the rope. Look for frays, cuts, kinks, or any signs of wear. For synthetic ropes, check for discoloration or fuzziness. These can indicate UV damage or abrasion. For steel cables, look for broken strands, rust, or flat spots.

Clean your rope regularly. Dirt and debris can get into the rope fibers. This causes internal abrasion. Use mild soap and water for synthetic ropes. Rinse them thoroughly and let them air dry completely. For steel cables, clean them with a wire brush. Then, apply a light coat of lubricant. This prevents rust and reduces friction.

Store your winch rope properly. Keep it out of direct sunlight and away from harsh chemicals. If your winch has a cover, use it. This protects the rope from the elements. Periodically unspool the entire rope. Then, respool it under tension. This helps prevent flat spots and ensures even layering. Following these maintenance tips keeps your rope in top condition. It also ensures your MARSHINE cable winch performs reliably for years.

Following these essential steps for selecting, preparing, attaching, and spooling your rope ensures a safe, efficient, and long-lasting installation on your cable winch. Regular checks and proper maintenance further enhance its reliability and performance. This aligns with MARSHINE's commitment to quality and user satisfaction.

Rope type significantly impacts safety and performance. Synthetic rope is lighter and safer if it breaks. Steel rope offers great durability. MARSHINE winches support both, ensuring optimal function for your specific needs.

Inspect your rope after every use for wear or damage. Clean it regularly. This extends its life and ensures safe operation. MARSHINE winches benefit from consistent care for lasting reliability. ✨

Incorrect spooling causes uneven wear and potential rope damage. It reduces efficiency and safety. Proper tension and even layering ensure your MARSHINE winch performs reliably. 🛠️