Leading electric hydraulic cable cutters for heavy-duty tasks often come from Greenlee, Milwaukee, and Klauke. These tools are known for robust performance, cutting capacity, and durability. Utility crews using a quality hydraulic cable cutter reduce repair times by 30%, and contractors boost productivity by 20%. MARSHINE recognizes the importance of a reliable cable cutter. This post details specific top models and their essential specifications for informed decisions.

The Greenlee ES750-18V stands out as a true powerhouse for heavy-duty cable cutting. This tool brings immense force to the job, easily slicing through large copper and aluminum cables. Its robust design ensures reliability on demanding worksites. Operators appreciate its consistent performance, making quick work of tough materials. Greenlee built this model for professionals who need maximum power and durability in their tools.

Milwaukee's M18 FORCE LOGIC 750 MCM offers an excellent blend of speed and user comfort. This hydraulic cable cutter quickly handles large cables, boosting productivity. It cuts through materials with impressive speed. For example, it achieves an average cut speed of just 3 seconds. Users also get more work done on a single charge. This tool delivers over 250 cuts per charge, minimizing downtime. Its ergonomic design reduces user fatigue, making it comfortable for extended use.

The Klauke EK60VP22 brings precision and versatility to the forefront. This tool is a favorite among professionals who require exact cuts and adaptability. Klauke designed it for various applications, from overhead lines to underground cables. Its advanced hydraulic system ensures clean, accurate cuts every time. This model combines German engineering with practical functionality, offering a reliable solution for complex tasks.

The RIDGID RE 600 shows impressive robustness, ready for the toughest jobs. This tool boasts a remarkable service interval of 32,000 cycles, highlighting its long-term durability. It operates with a powerful 6-ton hydraulic force output, making quick work of stubborn cables. The approximate cycle time for operation is a swift 5 seconds. This hydraulic cable cutter performs reliably across various conditions, functioning well within a temperature range of 15°F to 122°F (10°C to 50°C). An 18V Advanced Lithium Battery platform powers the tool. However, the RIDGID RE 600 SC ACSR model is a single-function tool. It comes with a non-interchangeable cutting head. This means it does not offer adaptability through interchangeable heads or jaw types for different applications.

The DEWALT DCE150D1 excels in portability and performance. This tool weighs approximately 6.75 lbs with the battery, making it easy to carry around the job site. Its inline design allows for easy access in tight spaces, such as panels and cable trays. This compact design enhances maneuverability. The DEWALT DCE150D1 cuts copper and aluminum cables up to 750 MCM. It features a powerful brushless motor. This motor provides long runtime and improved performance, ensuring the tool keeps working when you need it most.

A top-tier electric hydraulic cable cutter must handle various cable types and sizes. You need a tool that cuts through copper, aluminum, and even ACSR cables with ease. Different models offer varying capacities. For example, the Milwaukee M18 Force Logic cuts up to 1500 MCM for both copper and aluminum. The Klein Tools BAT207T44H handles 500 MCM copper and aluminum, plus 556 ACSR. A NEWTRY Hydraulic Cable Rebar ACSR Cutter can manage a 32mm diameter for all these materials.

| Cable Cutter Model | Copper Capacity | Aluminum Capacity | ACSR Capacity |

|---|---|---|---|

| Milwaukee M18 Force Logic | Up to 1500 MCM | Up to 1500 MCM | N/A |

| Klein Tools BAT207T44H | Up to 500 MCM | Up to 500 MCM | 556 ACSR |

| NEWTRY Hydraulic Cable Rebar ACSR Cutter | Up to 32mm (1.26 inches) diameter | Up to 32mm (1.26 inches) diameter | Up to 32mm (1.26 inches) diameter |

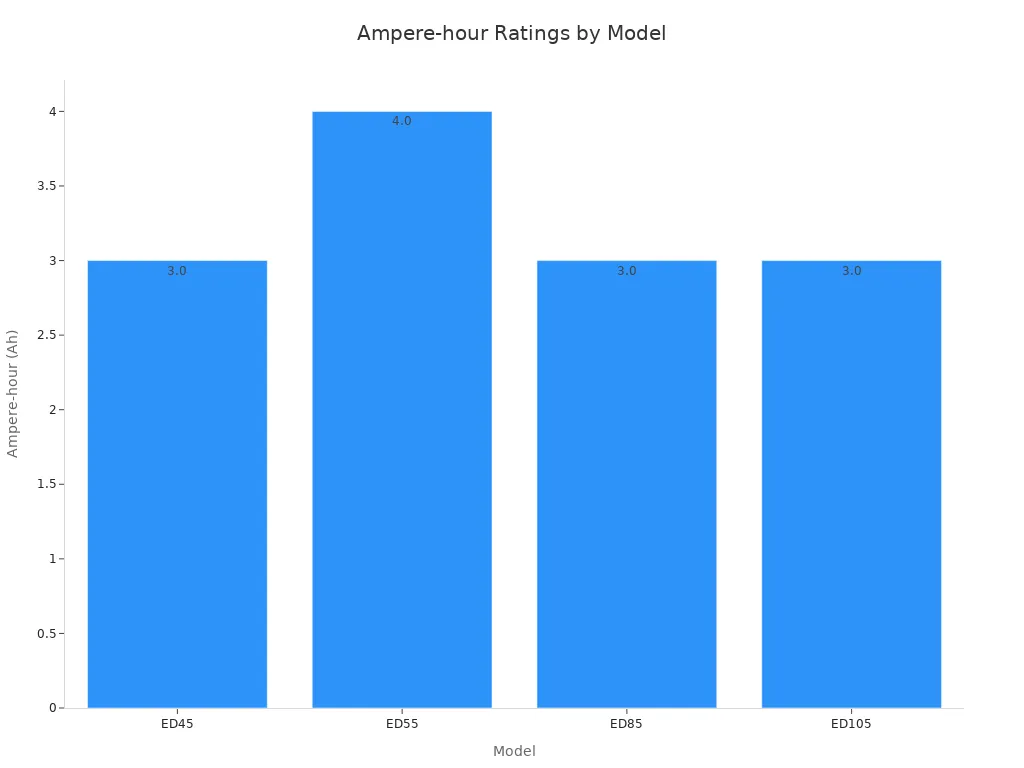

Long-lasting battery life and strong power output are crucial for heavy-duty work. You want a tool that keeps going without constant recharging. Most leading models use 18V batteries. Ampere-hour (Ah) ratings show how long a battery lasts. For instance, models like the ED45 and ED85 use 18V 3.0Ah batteries, while the ED55 uses an 18V 4.0Ah battery. Higher Ah means more work per charge.

| Model | Voltage | Ampere-hour |

|---|---|---|

| ED45 | 18V | 3.0Ah |

| ED55 | 18V | 4.0Ah |

| ED85 | 18V | 3.0Ah |

| ED105 | 18V | 3.0Ah |

Heavy-duty tools need to withstand harsh job site conditions. Look for robust construction and materials that resist wear and tear. Tools designed for job site readiness often feature sealed components to protect against dust and moisture. They also have strong housings to handle drops and impacts.

Safety always comes first. Leading cutters include features like automatic retraction after a cut, which prevents accidental re-engagement. Ergonomic designs reduce user fatigue. This means comfortable grips, balanced weight distribution, and easy-to-reach controls. These features make the tool safer and more pleasant to use for long periods.

The motor and hydraulic system are the heart of the tool. Efficient brushless motors provide more power and longer runtimes. An advanced hydraulic system ensures smooth, consistent cutting force. This combination delivers clean cuts and extends the tool's lifespan.

When selecting a tool, first consider the cables you cut most often. Do you primarily work with copper, aluminum, or perhaps tough ACSR? Each Hydraulic Cable Cutter boasts a specific maximum capacity. For instance, some models effortlessly slice through 750 MCM copper. Others handle much larger 1500 MCM cables. You must choose a tool that precisely matches your common cable types and sizes. This ensures you achieve efficient, clean cuts every single time.

Next, think about your typical job site conditions and how often you use the cutter. Are your work environments frequently dusty, wet, or extremely cold? Do you often need to operate in confined or tight spaces? Some tools feature robust, sealed components. These protect against harsh environmental factors. Other models offer compact, inline designs. These designs allow for superior maneuverability in cramped areas. If you use the tool daily, extended battery life and rapid charging capabilities become critical. For less frequent use, a durable and reliable model might suffice.

Finally, always evaluate the brand's reputation and its after-sales support. A strong brand often signifies a quality product and reliable performance. Look for manufacturers known for producing durable tools and offering excellent customer service. MARSHINE, for example, commits to quality and provides a complete after-sales system. This includes thorough quality tracking and continuous service monitoring. Good after-sales support ensures you can easily obtain parts and service when needed. This minimizes costly downtime and effectively protects your investment.

For heavy-duty tasks, leading electric hydraulic cable cutters consistently come from Greenlee, Milwaukee, Klauke, RIDGID, and DEWALT. Each brand offers distinct advantages in power, speed, or versatility. Selecting the best one depends on specific cable types, sizes, and operational demands. Investing in a top-tier tool ensures reliability, efficiency, and safety for rigorous work.

Heavy-duty cutters handle large, tough cables like 750 MCM copper or ACSR. They feature powerful motors, robust hydraulic systems, and durable construction. These tools perform reliably on demanding job sites. strongly

Users match the cutter's capacity to their typical cable types and sizes. They check the maximum diameter or MCM rating the tool can cut. This ensures efficient and clean cuts every time.

Yes, leading models include important safety features. These often involve automatic retraction after a cut and ergonomic designs. Always follow manufacturer guidelines for safe operation.

-