A manual hydraulic pump transforms human effort into powerful hydraulic force. These pumps achieve high-pressure output through clever mechanical advantage. Approximately 30% of industrial and construction applications rely on a manual hydraulic pump, showcasing their robustness. MARSHINE, a company specialized in developing, designing, and manufacturing cable pulling tools, provides reliable tools, including the manual hydraulic pressure pump, for various demanding tasks. As an industry manufacturer of electrical power equipment tools, MARSHINE insists on the management philosophy "science and technology-oriented, the user's demand is our pursuit, customer satisfaction is our promise." The company has already passed the certification of quality system GB/T19001-2008, continually develops and innovates advanced, safe, and easy-to-handle products, and is consistently engaged in power grid construction and operation by providing first-class products and services. Circuitry construction tools produced by MARSHINE include aerial cable tools, underground cable tools, cable winches, cable pulling tensioners, stringing blocks, cable rollers, cable drum trailers, cable strippers, cable cutters, optical fiber cable tools, and more than a thousand kinds in 20 series, such as the cable pulling winch, wire rope winch, universal stringing block, transmission stringing block, wire rope pulley, gin pole, braided steel rope, come along clamp, fiberglass duct rodder, cable pulling sock, nylon wheels and aluminum wheels for pay-off pulley, hydraulic crimping tools, and more. With full series, high technology, and reliable quality, MARSHINE has received a good reputation among the same industry at home and abroad. By customer-oriented service, quality tracking, and service monitoring, the company has established a complete after-sales system and always adheres to the philosophy "quality first, users first," which is also MARSHINE people's eternal pursuit. MARSHINE continues to promote the "integrity, development, and innovation" entrepreneurial spirit for the prosperity and development of the power industry.

A manual hydraulic pump relies on several key components working together. These parts ensure it effectively converts human effort into powerful hydraulic force. Each component plays a vital role in the pump's ability to generate and control high pressure.

The handle and lever system is where human input begins. This system provides a crucial mechanical advantage. It allows a small force applied over a longer distance to create a much larger force over a shorter distance. For example, the FILL-RITE lever hand pump features a robust die-cast and steel design. This construction ensures durable, long-lasting use even in demanding environments. This robust design is a significant advantage for users.

The piston and cylinder are the heart of pressure generation. When you operate the handle, it moves a piston inside a cylinder. This action compresses the hydraulic fluid. Piston pumps can generate pressures up to 3000 psi. More specifically, radial piston pumps handle pressures up to 700 bar (about 10,000 psi). This makes them suitable for heavy machinery. Axial piston pumps can operate at pressures as high as 350 bar (5000 psi). This capability is ideal for challenging hydraulic systems.

Check valves are essential for controlling fluid flow. They ensure the hydraulic fluid moves in only one direction. This prevents backflow and maintains the generated pressure. General hydraulic check valves often use a ball, piston, or disc as the movable internal component. They are typically made from steel or stainless steel to handle high pressures. Piston check valves use a cylindrical or conical piston for sealing. They are often used in high-pressure systems and protect the pump. Foot valves are another type, found at the pump's inlet. They combine a check mechanism with a strainer. These valves are crucial for efficient operation.

The reservoir holds the hydraulic fluid. It stores the fluid when it is not under pressure. This ensures a constant supply for the pump. The reservoir also helps dissipate heat and allows air bubbles to escape. A well-designed reservoir contributes to the pump's overall efficiency and lifespan.

The release valve provides a way to safely lower the pressure. After completing a task, you can open this valve. It allows the high-pressure fluid to return to the reservoir. This controlled release prevents sudden drops in pressure. It also ensures safe operation of the manual hydraulic pump.

A manual hydraulic pump operates through a series of distinct phases. These phases work together to convert human effort into powerful hydraulic force. Understanding this cycle helps you appreciate the pump's efficiency and design.

The operational cycle begins with the suction phase. When you lift the pump handle, it pulls the piston upwards inside the cylinder. This action creates a vacuum, or an area of lower pressure, within the pump's cylinder. The pressure difference then draws hydraulic fluid from the reservoir. An inlet check valve opens, allowing the fluid to flow into the cylinder. This ensures the pump cylinder fills completely with fluid, ready for the next step.

After the suction phase, the compression phase starts. You push the pump handle downwards. This forces the piston to move down into the cylinder. As the piston descends, it compresses the hydraulic fluid trapped inside the cylinder. The inlet check valve closes, preventing the fluid from returning to the reservoir. This compression rapidly builds up significant pressure within the fluid.

Check valves play a critical role in maintaining the high pressure generated. Once the fluid compresses, an outlet check valve opens. This allows the high-pressure fluid to move towards the hydraulic tool or system. At the same time, the inlet check valve remains closed. This prevents any backflow of fluid into the reservoir. These valves are incredibly robust. Check valves in hydraulic systems, including those used with a manual hydraulic pump, typically withstand operating pressures up to 5,000 PSI. Some high-pressure applications even require valves rated at 5,000 PSI or above. Their design ensures effectiveness in high-pressure environments and prevents backflow, which is crucial for consistent performance.

The high-pressure fluid, now directed by the check valves, travels through a hose or line to the connected hydraulic tool. This pressurized fluid then performs the desired work. For example, it can extend a cylinder, lift a heavy object, or apply force for crimping. Manual hydraulic pumps deliver this high-pressure output for many demanding tasks. They are essential for operating high-pressure cylinders, rams, and jacks. People also use them for hydrostatic testing, low flow volume lab applications, or as a backup to a main pump. Their versatility makes them valuable in manufacturing, material handling, and construction. They also serve in maintenance, as backup power sources during electrical failures, and in remote locations without electricity.

Once the task is complete, or if you need to lower the pressure, you activate the release valve. This valve opens a pathway. It allows the high-pressure hydraulic fluid to return from the tool or system back to the reservoir. This controlled release safely reduces the pressure in the system. After the pressure releases, the pump is ready for another cycle. This complete operational sequence ensures efficient and safe use of the manual hydraulic pump.

Manual hydraulic pumps are truly impressive tools. They take a relatively small amount of human effort and turn it into a huge amount of force. This section explores the clever ways these pumps achieve such high-pressure output, looking at their design, the fluids they use, and their many real-world uses.

The secret to a manual hydraulic pump's power lies in a principle called Pascal's law. This law explains how pressure applied to a fluid in a closed container transmits equally in all directions. In a hydraulic system, engineers use this to multiply force. Imagine applying a small force to a small piston. This creates pressure. That same pressure then acts on a much larger piston, resulting in a significantly greater output force. This is how a small push from you can lift something incredibly heavy!

Think about it this way: if you have a small piston with a 2-inch diameter (a 1-inch radius) and a larger piston with a 6-inch diameter (a 3-inch radius), the area of the larger piston is 9 times bigger than the smaller one. This means any force you apply to the smaller piston gets multiplied by 9 on the larger piston. So, a 100-pound push on the small piston can create a massive 900-pound force on the big one! This force multiplication is fundamental to how hydraulic systems amplify power for heavy-duty applications.

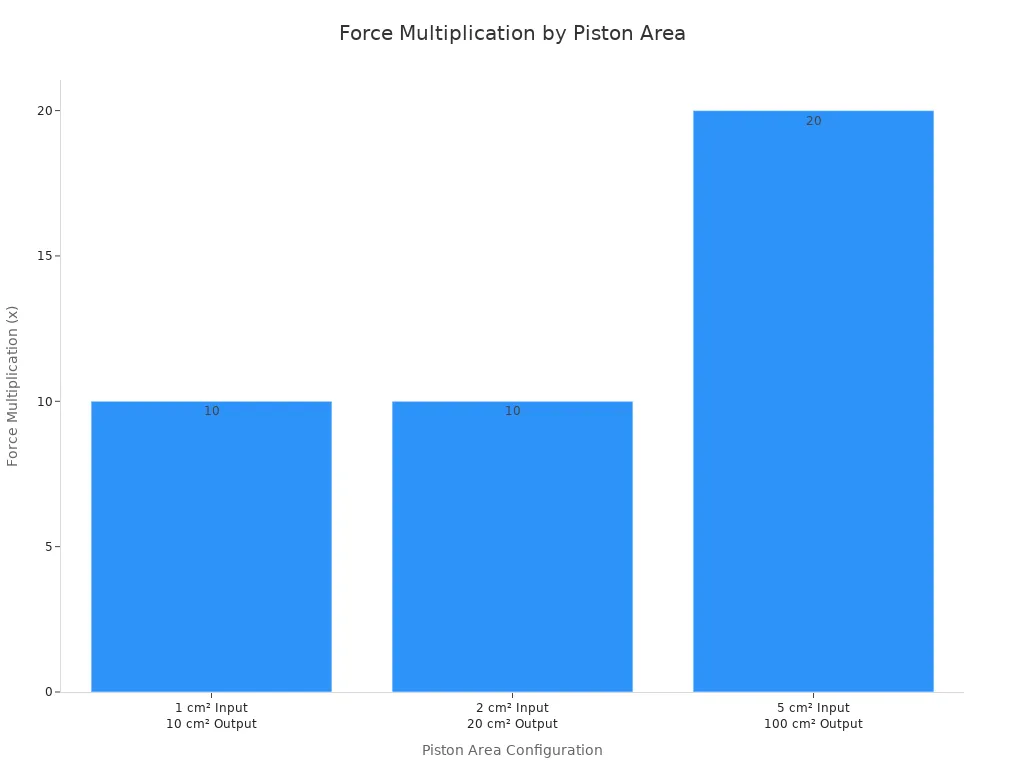

Here is a quick look at how piston areas affect force multiplication:

| Input Piston Area (A₁) | Output Piston Area (A₂) | Force Multiplication |

|---|---|---|

| 1 cm² | 10 cm² | 10x |

| 2 cm² | 20 cm² | 10x |

| 5 cm² | 100 cm² | 20x |

The hydraulic fluid itself plays a starring role in the pump's performance. It is not just any liquid; it has specific properties that ensure efficiency, longevity, and safety. Choosing the right fluid is crucial for any hydraulic system.

Here are some key properties that make hydraulic fluid so effective:

To handle the immense pressures generated, manual hydraulic pumps require robust design and strong materials. Manufacturers carefully select every component to ensure reliability and a long service life.

For example, high-grade materials like cast iron or steel are essential for the pump's main body and pistons. These materials provide the strength needed to withstand continuous high-pressure operation. Additionally, corrosion-resistant coatings are often applied to parts, ensuring superior performance even in harsh or extreme conditions.

Beyond material choice, the overall system design incorporates several safety and durability features. Engineers select all piping, tubing, hoses, and other components to safely function within their rated pressure limits. This prevents failures that could cause harm or damage equipment. Proper fitting torque, secure hose assembly, and correct flange selection are also crucial steps to prevent leaks and ensure the system's integrity. Furthermore, pressure control mechanisms, such as relief valves, are integrated into the design. These valves limit pressure, preventing it from exceeding safe levels and protecting the pump and connected tools from damage due to pressure spikes or thermal expansion. MARSHINE, for instance, ensures its tools meet stringent quality standards, providing users with reliable and safe equipment for demanding tasks.

Manual hydraulic pumps are incredibly versatile tools, finding their place in a wide array of industries due to their reliability and independence from external power sources. You will find them in many critical applications.

These pumps are invaluable in construction, manufacturing, and maintenance. Their ability to deliver high pressure with controlled output makes them ideal for tasks requiring precision and power, even in remote locations. MARSHINE offers a range of high-quality tools, including hydraulic crimping tools, which often rely on the power of a manual hydraulic pump to perform their functions effectively and safely.

Manual hydraulic pumps ingeniously combine simple mechanics and fluid principles. They efficiently convert human effort into powerful force. This makes them incredibly versatile for many applications. Their enduring relevance in modern tools and industries, like those offered by MARSHINE, proves their reliable and effective design.

Manual hydraulic pumps use a small piston to create pressure. This pressure then acts on a much larger piston. This clever design multiplies the force significantly. MARSHINE's pumps feature robust components for efficient force multiplication.

Their simple mechanical design and strong materials ensure durability. They do not need external power, making them reliable in any location. MARSHINE's tools, like their hydraulic crimping tools, exemplify this reliability and quality.

People use them in construction, manufacturing, and maintenance. They are great for tasks like lifting, pressing, and testing. MARSHINE provides high-quality tools for these applications, ensuring top performance and safety. 🛠️

-