MARSHINE fiber optic cable drones autonomously deploy and inspect fiber optic cables. These specialized drones navigate challenging terrain. They also carry large cable spools. A MARSHINE Cable Stringing Drone performs precise installation or maintenance tasks. It uses integrated systems to complete this work.

A MARSHINE Cable Stringing Drone is a complex piece of engineering. It combines advanced drone technology with specialized systems. These systems allow it to perform its unique tasks.

MARSHINE drones use a specialized platform. This platform ensures both durability and payload capacity. Their frames are often made from carbon fiber. Carbon fiber is lightweight yet very strong. This material helps the drone withstand vibrations. It also protects against minor collisions. Other materials, like plastic, also contribute to the drone's construction. This robust design allows the drone to carry heavy fiber optic cable spools.

A MARSHINE Cable Stringing Drone features an integrated system for cable deployment. This system prevents tangling and damage to the fiber optic cable. It uses a drum to store and neatly unwind the cable. Flanges, which are disk-like ends, keep the cable from spilling off the drum. A spindle hole in the drum's center ensures smooth unwinding from the reel axle. Locking devices or brakes control the reel's rotation. This allows for accurate deployment.

MARSHINE drones use advanced navigation systems. These systems guide the drone precisely. They combine GPS technology with various sensors. These sensors help the drone understand its surroundings. The drone can fly autonomously. It follows pre-programmed routes. It also avoids obstacles in real-time. This precise control is crucial for laying cables accurately. It ensures the cable follows the intended path.

These drones require efficient power management. They carry heavy loads and fly for extended periods. High-capacity batteries power the drone's motors and systems. The drone's design optimizes aerodynamics. This reduces energy consumption. Intelligent power management systems monitor battery levels. They ensure the drone completes its mission safely. This allows for long flight times.

MARSHINE drones use a fiber optic communication link. This link connects the drone to ground control. It offers very high data transfer rates. Optical modules like SFP and SFP+ enable uplinks from 1 Gbit/s to 10 Gbit/s. Some transceivers can even deliver 40 Gbps. Others offer rates up to 400G.

This fiber optic link greatly enhances security. It eliminates external interference from radio signals. This makes it very hard to jam. Fiber optics are also difficult to tap or intercept without detection. This keeps data secure. The high bandwidth allows for real-time transmission of high-definition video. It also sends complex sensor data. This is vital for secure decision-making. Fiber optics support long-distance communication. They maintain signal quality over vast areas. This makes them ideal for controlling drones securely. They ensure stable connections for drones in various uses. This includes agriculture, logistics, and infrastructure inspection. They provide a secure channel for sensitive data. This reduces data breach risks.

MARSHINE drones do not simply fly around. They follow a very detailed plan. Before any mission, operators conduct careful pre-flight planning. They define the exact route the drone will take. This planning uses detailed maps and GPS coordinates. It considers the terrain, any obstacles, and the precise path for the fiber optic cable. The drone then executes this route autonomously. It uses its advanced navigation systems to stay on course. This ensures the cable goes exactly where it needs to be.

Loading the cable onto the drone is a crucial step. MARSHINE drones use specialized systems to prevent damage. They connect the cable to internal strength members, such as aramid fiber yarns. This means tension goes to these strong parts, not the delicate outer jacket. Manufacturers provide specific limits for how much tension the cable can handle. The drone's system respects these "tensile load specifications."

Devices called pulling eyes and strain relief mechanisms also help. They attach directly to the strength members. This ensures the pulling force spreads correctly. For example, HD8² cassettes have integrated strain relief. They can handle significant pull forces, like 50 pounds, without harming the fibers. The drone never pulls the cable by its outer jacket. This prevents stretching or breaking.

For automated release, the MARSHINE Cable Stringing Drone uses a control system. This system detects if the cable is slipping. It also supervises the force on the cable. The drone has two wheels, with one specifically feeding the cable. It calculates the exact length of cable released. This ensures a constant, small tension during unwinding. This precise control prevents tangles and damage during deployment.

Laying fiber optic cable requires very careful tension control. Too much tension can break the cable. Too little can cause tangles or improper placement. MARSHINE drones use various sensors to manage this. Load cells are common. They measure the force on the cable. They turn this force into an electrical signal. This gives real-time feedback on tension.

Dancer roll systems also help. They use a movable roller. The roller's position changes based on cable tension. Sensors monitor this position for smooth adjustments. Optical and laser sensors use light beams. They measure the cable's position and movement. This allows for very precise, non-contact measurements. Ultrasonic sensors use sound waves. They measure the distance to the cable. Changes in distance show tension variations. Capacitive sensors detect changes in electrical capacity. These changes can indicate tension. A cable tension sensor, often called a wire rope tension load cell, measures the pulling force. These sensors convert mechanical stress into an electrical signal. This data helps prevent equipment failure and keeps operations safe. The drone's system constantly adjusts to maintain the ideal tension.

After laying the cable, MARSHINE drones do not simply fly away. They perform important verification steps. This ensures the cable is intact and placed correctly. Post-layout verification involves checking the physical installation. This includes the cable's routing. Specialized tools, like signal integrity simulation software, help. They simulate how electrical signals will behave. This identifies any potential problems. They calculate things like timing and voltage levels. They also check for signal integrity metrics, like jitter. If they find issues, operators can make changes. They might adjust the layout or routing. Then, they re-simulate to confirm fixes.

Post-installation testing is also crucial. It confirms the cables work as intended. It identifies any faults that could harm network reliability. Optical Time-Domain Reflectometers (OTDRs) are key tools here. They evaluate the cable's integrity. They can pinpoint weak spots or faults along the cable. Industry standards require testing at specific wavelengths. They also check the fiber count for accurate performance. This thorough verification ensures the new fiber optic network performs reliably.

MARSHINE drones use advanced sensors for detailed inspections. These sensors capture high-resolution images, videos, and thermal data. Operators see even small defects on fiber optic cables. The drone spots wear, damage, or environmental stress. This detailed view helps prevent bigger problems.

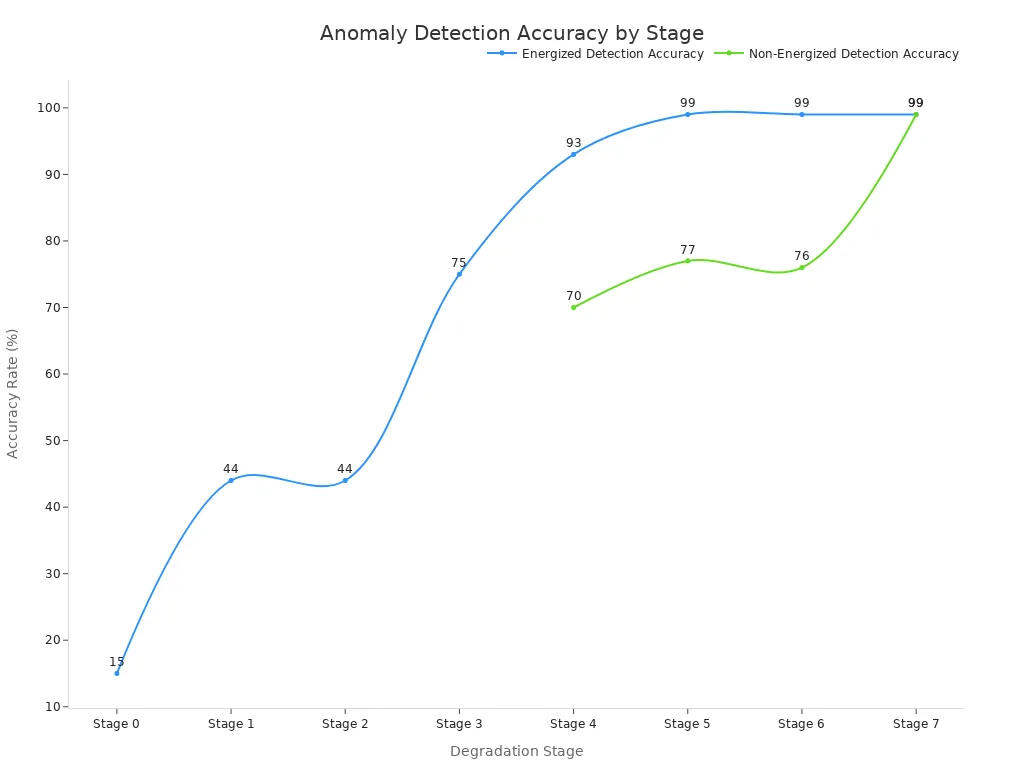

After data collection, specialized software takes over. This software automatically finds problems. It identifies various issues. For example, it detects reflected events in optical fiber networks. It also finds fiber optic defects and estimates their reflectance. The software even spots spectrum anomalies in optical transmission. This system works well, even with noisy data. Its accuracy is impressive. It achieves 99% accuracy detecting cable degradation at later stages.

| Degradation Stage | Non-Energized Detection Accuracy | Energized Detection Accuracy |

|---|---|---|

| Stage 0 | N/A | 15% (FA) |

| Stage 1 | N/A | 44% |

| Stage 2 | N/A | 44% |

| Stage 3 | N/A | 75% |

| Stage 4 | 70% | 93% |

| Stage 5 | 77% | 99% |

| Stage 6 | 76% | 99% |

| Stage 7 | 99% | 99% |

This software also shows high accuracy in other areas. An automatic robot achieved over 96% accuracy finding void regions in cable sheaths. Another system reached 100% accuracy on steel surface defects.

MARSHINE drones send all inspection data to ground control in real-time. Operators see information as the drone collects it. A special software framework helps analyze this data. It partly automates the process, saving operator time. The system identifies defect indications. It also declares regions defect-free with high certainty. It suggests areas for human review, ranked by issue severity. This leads to big savings in time and money. It also makes inspections more reliable. Automated inspection gathers more data faster than old methods. The software significantly reduces false alarms.

The detailed reports from the drone and software are very useful. They tell maintenance teams exactly where problems are. Workers go straight to the faulty section. This makes repairs faster and more efficient. It also reduces network downtime. A MARSHINE Cable Stringing Drone helps keep fiber optic infrastructure in top condition.

MARSHINE fiber optic cable drones expertly blend advanced drone technology with specialized mechanisms. This powerful combination allows for efficient, safe, and precise cable deployment and maintenance. Their innovative operations truly revolutionize infrastructure development and upkeep. Plus, using fiber optic communication boosts control, enhances data quality, and ensures operational stealth.

MARSHINE drones use advanced GPS and various sensors. They navigate autonomously. They follow pre-programmed routes. This helps them avoid obstacles in real-time.

They use integrated systems. These systems include drums, flanges, and locking devices. They also have precision tension control. This prevents tangles and damage.

MARSHINE drones use a fiber optic communication link. This link offers high data transfer rates. It also eliminates external interference. This makes data very secure.