Cable rollers are mechanical devices that guide and support cables. They prevent damage during installation, maintenance, and repair. Their primary function ensures efficient, safe cable laying. The global cable rollers market was valued at $500 million in 2020 and is projected to reach $200 million by 2025, showing their critical role. The cord and cable reels market is also expected to grow to $10.43 billion by 2029. MARSHINE, a leading manufacturer, develops advanced cable reel roller solutions for this expanding industry.

Cable rollers are not just simple tools; they are essential components that ensure the integrity and efficiency of cable laying operations. Their design focuses on two main objectives: protecting valuable cables from harm and making the installation process as smooth as possible.

One of the most critical functions of cable rollers is to prevent damage to cables during installation. Without proper guidance, cables can suffer from various issues. For example, cables can develop kinks or twists, especially when workers pull them over trenches. They can also experience abrasions, scratches, or even severing if pulled across rough surfaces or sharp edges. These types of damage compromise the cable's performance and lifespan.

Cable rollers actively prevent these problems. They feature smooth bearings or bushings that ensure consistent spinning with minimal friction. This design reduces friction between the cable and the roller's frame, making it much easier to move the cable. Bearings also allow the roller to rotate freely, further minimizing resistance. For specific situations, such as pulling cables through manholes, manhole cable rollers have a curving shape with three rollers. This design reduces friction and traction during the pulling process. Similarly, bell mouth cable rollers and split lock roller guides protect both the cable and the duct. They ensure the cable passes smoothly over the roller without touching the duct when going through conduits. MARSHINE, as a specialized manufacturer, focuses on developing advanced and safe products. Their cable rollers are designed with these protective features, ensuring cables remain intact and undamaged.

Beyond preventing damage, cable rollers significantly facilitate the installation process. They provide a smooth surface for cables to pass over, which is crucial for efficient operations. This smooth passage minimizes friction between cables and the surfaces they cross, especially over long distances. The rollers turn with the cable, and their wide, smooth surfaces reduce pressure on the cable's insulation, keeping it intact.

This reduction in friction is vital for maintaining cable integrity and also for improving efficiency. Cable rollers are often installed on bearings to reduce installer fatigue, making the job less physically demanding. Materials like nylon and aluminum provide minimum resistance for cable installation without damaging the cable jacket. The use of cable rollers can significantly improve efficiency in terms of time and effort, enhancing labor productivity and cable support. For instance, some systems using rollers can achieve a 50% reduction in average installation time compared to systems without them. MARSHINE's commitment to providing first-class products and services means their cable rollers are engineered to make cable installation faster, safer, and more efficient for power grid construction.

Cable rollers are more than just simple tools. They bring many important advantages to cable laying projects. These benefits range from making work safer to saving money and handling tough conditions. They truly make a difference in how teams manage cable installations.

Using cable rollers significantly improves safety and makes work much faster. When workers install cables, they often deal with heavy, long materials. Without rollers, they might have to lift and drag these cables manually. This can lead to injuries or accidents. Cable rollers guide cables smoothly across surfaces and around bends. This reduces the need for manual lifting and dragging. Their nylon wheels also reduce friction, which allows for faster cable pulling with less physical effort. This is especially helpful for heavy cables or long projects. Positioning many rollers along the cable path avoids sharp bends and makes the whole process easier and more efficient. This means workers get less tired, and the job gets done quicker and more safely.

Cable rollers also help save money and reduce waste in the long run. Cables are expensive, and damaging them during installation can lead to big costs. Rollers prevent common problems like kinks, twists, and scrapes. These issues can harm the cable's performance and how long it lasts. By protecting the cable, rollers reduce the risk of damage or project delays. This lowers overall costs for cable installation projects.

Consider the types of damage rollers prevent:

Preventing these issues means fewer repairs and less downtime. This balances the initial cost of the rollers and leads to long-term savings.

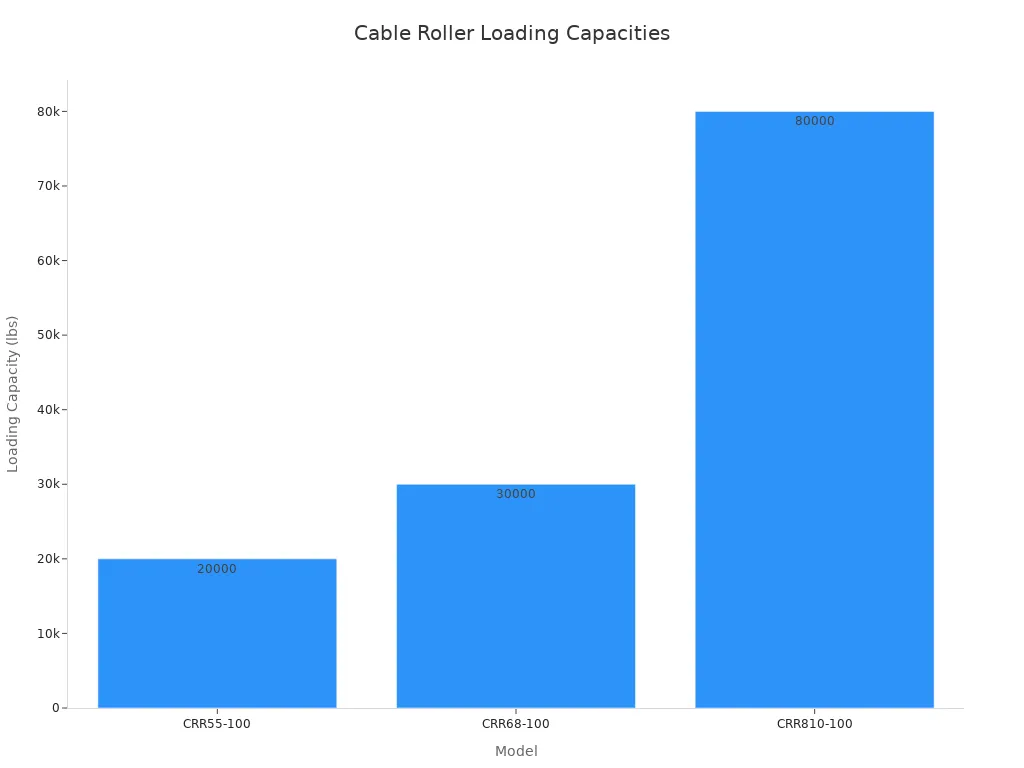

Cable rollers are versatile tools. They can handle many different types of cables and work well in various environments. Cables come in all sizes and weights, and rollers are designed to support them. For example, a 20-inch cable tray roller can handle cable pulling loads up to 2,000 lb. For even heavier tasks, cable drum rollers offer loading capacities from 20,000 to 80,000 lbs (10-40 ton).

| Model | Loading Capacity |

|---|---|

| CRR55-100 | 20,000 lbs (10-ton) |

| CRR68-100 | 30,000 lbs (15-ton) |

| CRR810-100 | 80,000 lbs (40-ton) |

Standard cable rollers can support weights from 500kg to 3000kg. This wide range means there is a roller for almost any cable size.

Rollers also need to withstand tough environmental conditions. Cables themselves are often made to handle extreme temperatures, moisture, chemicals, and UV light. Similarly, cable rollers must endure heat, dirt, humidity, moisture, chips, and both hot and cold temperatures. These conditions are common in harsh places like composting plants or waste incineration facilities. In such environments, reliable operation is critical to avoid expensive machine breakdowns. When choosing cable rollers, it is important to check their resistance to moisture, chemicals, or extreme temperatures. This is especially true if they will be used outdoors or in other challenging settings.

Different cable laying jobs need different tools. Cable rollers come in various designs, each built for a specific task. Understanding these types helps teams choose the right equipment for efficient and safe cable installation.

When laying cables in open trenches, straight line cable rollers are essential. They guide cables smoothly over long distances. These rollers prevent the cable from dragging on the ground or getting damaged. Many types exist for different cable sizes and trench conditions. For example, compact rollers like the SLR1 handle cables up to 90mm in narrow trenches. Heavy-duty options, such as the SLR4, support cables up to 130mm. MARSHINE offers a range of these rollers, built with durable materials.

Here are some common types and their features:

| Cable Straight Roller Type | Material | Key Features |

|---|---|---|

| Ground Cable Roller, aluminium | Abrasion resistant aluminium rollers, galvanized steel tube frame | Dust- and soil proof ball bearings, large ground clearance |

| Ground Cable Roller, synthetic | Non-aging and weatherproof, extreme light weight | Stackable, large ground clearance, for cables up to Ø 100 mm |

Frames often use Q235 carbon steel or galvanized steel, while rollers are typically aluminum or nylon. These materials ensure durability and smooth operation.

Cables rarely run in a perfectly straight line. When a trench or path bends, corner cable rollers become indispensable. They guide cables around turns without causing kinks or excessive stress on the cable's outer jacket. This makes pulling cables much easier and safer around bends. MARSHINE designs its corner rollers to handle these directional changes smoothly, protecting the cable's integrity.

Some environments demand more than standard rollers. For uneven or rocky terrain, specialized cable rollers provide extra support and stability. U-shaped rollers, for instance, feature a groove that cradles the cable, making them excellent for bumpy surfaces and long runs. Adjustable rollers offer flexibility, adapting to various ground conditions.

| Roller Type | Best Terrain | Cable Support | Flexibility |

|---|---|---|---|

| U-Shaped Roller | Uneven, Rugged | High | Medium |

| Adjustable Cable Rollers | All Types (Configurable) | Variable | High |

For underwater cable laying, equipment needs even more specialized features. These systems use large-diameter rollers and wear-resistant materials to protect cables during installation on the seabed. They also include motion-compensated systems to stabilize cables in rough seas. MARSHINE develops robust solutions for all challenging terrains, ensuring reliable performance.

Cable rollers are truly essential for modern cable laying. They protect cables and make installations efficient. Investing in quality cable rollers, like those from MARSHINE, ensures successful infrastructure development. This commitment to quality guarantees long-lasting performance and safety for every project.

Cable rollers protect cables from damage during installation. They also make the process smoother and safer for workers. MARSHINE's rollers ensure cable integrity and efficient laying.

MARSHINE provides straight line rollers for open trenches and corner rollers for turns. They also have specialized rollers for challenging terrains. This full range meets diverse project needs.

Rollers prevent expensive cable damage and reduce installation time. This minimizes repairs and material waste. MARSHINE's durable rollers provide long-term savings and efficiency.

-