Choosing your next hydraulic punching machine feels like a big decision, doesn't it? I want to help you make an informed choice and navigate this process with real confidence. The market for these machines is significant, valued at USD 823.90 million in 2018, and it's still growing, projected to increase by 4.7% annually. This means optimizing your investment, whether it's for a new hydraulic punching machine or even specialized Hydraulic Crimping Tools, is key for your long-term operational success.

Before looking at machine models, I always tell people to really dig into what you need the machine to do. This step is super important for picking the right hydraulic punching machine.

First, think about your materials. Hydraulic punching machines excel at making holes in various fabrics. I've seen them used for curtain eyelets, heavy-duty outdoor fabrics, and automotive upholstery. They also punch or cut metal plates. For metal, these machines handle thicknesses from about 12 mm (0.47 inches) up to 50 mm (1.97 inches), including stainless steel, aluminum, and light steel. Here’s a quick look at some common material thickness limits:

What shapes and sizes will you punch? A versatile machine handles many profiles like flat bars, steel sheets, pipes, and angles. I've seen them make holes from 2mm to 28mm in angles, or flatten and cut pipes. They can even cut round solid bars up to 35mm. You might also need to make lock holes or notch pipes. Consider these capabilities:

Now that you know what you need your machine to do, let's look at the numbers. These specifications help you match the machine to your production goals.

Tonnage is super important. It tells you how much force your hydraulic punching machine can apply. I think of it like the machine's strength. If you work with thick steel or tough materials, you need higher tonnage. For example, a machine with 50 tons of working pressure, like the CH-80B model, can handle a lot. Always make sure your chosen tonnage exceeds your maximum material thickness and hardness.

Stroke length is how far the punch travels. Speed is how fast it moves. Both affect how quickly you can get your work done. I've seen different models offer various speeds and stroke lengths. For instance, some machines can have a piston stroke of 70 mm (adjustable). When it comes to speed, you might see:

Some machines can even reach 400 strokes per minute with standard hydraulics, or up to 800 spm with high-speed hydraulics!

The throat depth is the distance from the center of the punch to the machine's frame. This measurement tells you how large a piece of material you can fit into the machine. For example, a model like the CH-80B has a throat depth of 85mm. A larger throat depth means you can punch holes further from the edge of a wide sheet or plate.

After looking at the specs, I always think about how a machine actually performs. This part helps me understand its real-world value.

I know speed matters a lot. How fast can the machine punch a hole? How quickly can it complete a full cycle? Faster punching speeds mean I can produce more parts in less time. This directly impacts my productivity. I always compare the cycle times of different models. A quicker cycle time means more output for my business.

I also consider the long-term costs. How much energy does the hydraulic punching machine use? More efficient machines save money on electricity bills. I look for models that are designed to be energy-efficient. Lower operating costs mean a better return on my investment over time. It's not just about the purchase price; it's about what it costs to run every day.

Nobody wants a super loud or shaky machine. I pay attention to noise levels and how well a machine controls vibration. A quieter machine makes the workplace better for everyone. Good vibration control also means the machine is more stable. This can lead to more accurate punches and a longer machine life.

I always look for machines that are easy to use. Modern hydraulic punching machines are designed with user-friendly interfaces. This really simplifies programming and control. It means I can get more done, and new operators learn faster. I've seen how advancements in software make interfaces more intuitive. This makes it easier to program complex tasks. Look for features like user-friendly controls, clear interface screens, and intuitive programming. Touchscreen CNC controls are a big plus. Preset libraries for common operations save a lot of time. Diagnostic prompts and alerts are also helpful. If it's a CNC machine, programmable part layouts, automatic tool change, and pattern memory are great features.

In this section, I've highlighted how important it is to evaluate a machine's performance and efficiency. I consider speed, energy use, noise, and how easy it is to operate. These factors help me choose a machine that works well and saves money.

When I choose a machine, I always think about how long it will last and how much work it will need. Durability and easy maintenance are super important for keeping things running smoothly.

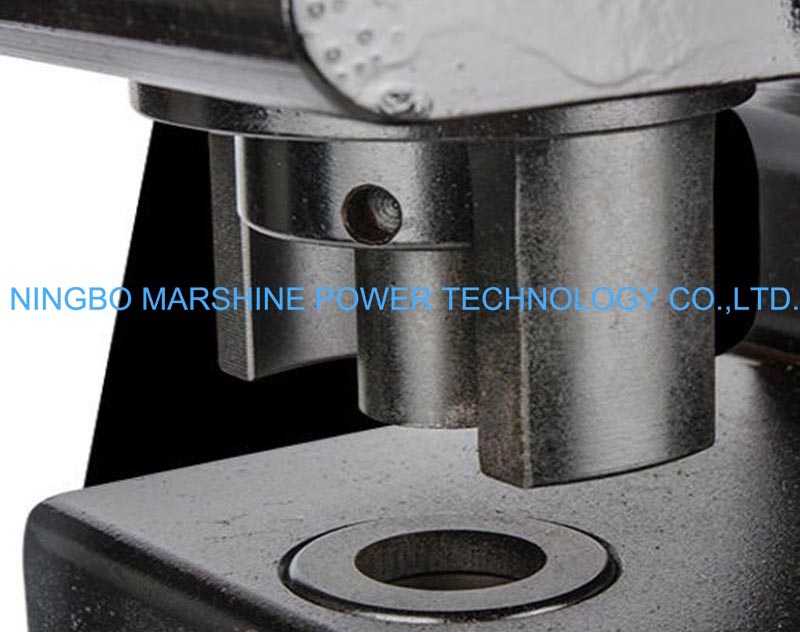

I always look closely at how a machine is built. A strong, well-made frame and high-quality materials mean the machine can handle tough jobs for years. I want to see solid welds and robust components. This tells me the manufacturer cares about longevity.

I also consider the individual parts. Are the hydraulic cylinders, pumps, and electrical systems from reputable brands? Reliable components mean fewer breakdowns and less downtime. I look for machines where the manufacturer stands behind the lifespan of these critical parts.

Every machine needs care, and a hydraulic punching machine is no different. I always check the recommended maintenance schedule. It helps me plan for upkeep. For example, I know I'll need to clean the machine surface daily and inspect the operating rate and noise. Weekly, I clean the motion guide rail. Monthly, I clean the cooler for hydraulic oil, lubricate the guide rail, and inspect the oil pressure.

Daily Maintenance often includes:

- Replacing or regrinding tooling.

- Inspecting clutch pins and brake components for wear, then applying high-temperature grease.

- Cleaning oil distribution tubes; lubricating slide rails, screws, and sliders.

- Checking oil circuits and pumps for leaks.

- Tightening loose electrical contacts; checking wiring for damage; testing solenoid valves and control relays.

Monthly tasks usually involve monitoring hydraulic oil pressure and temperature, replacing filters, and inspecting hoses. Annually, I expect a more thorough overhaul, including inspecting gears, belts, and frame welds.

Finally, I always make sure spare parts are easy to get. If a part breaks, I don't want to wait weeks for a replacement. Good availability means I can fix issues quickly and keep my production on track.

This section helps me understand the long-term commitment and cost of owning a machine. I want a durable machine that is easy to maintain.

When I look at any heavy machinery, safety is always at the top of my list. A hydraulic punching machine is powerful, so it needs robust safety features to protect everyone.

I always check for easy-to-reach emergency stop buttons. These are super important! They are usually big, red, mushroom-shaped buttons right on the control panel. If something goes wrong, hitting that button immediately stops the machine. It's a mandatory feature, and I make sure it's always visible and accessible.

Physical barriers are key. I look for steel ejection curtains that protect operators from flying debris. These curtains let you see what's happening but keep you safe. Sometimes, I even see ballistic protection blankets for extra safety during extreme operations. Interlock kits are also great; they prevent guards from opening while the machine is running. Plus, the main power disconnect switch should always be lockable in the "Off" position for maintenance.

Overload protection is like a safety net for the machine and the operator. I know it prevents damage to important parts like the hydraulic pump and the punching die. This means the machine lasts longer and needs fewer repairs. It also keeps operators safe from unexpected force releases. For me, it brings peace of mind, knowing the machine won't break down unexpectedly and will keep producing quality parts.

I think about the person using the machine all day. Good ergonomics make a big difference. I look for adjustable work heights so operators can set the machine to a comfortable level. User-friendly interfaces with clear labels and touch screens also make operation easier and safer. Enhanced visibility, like lighted work areas, helps prevent errors. Plus, hydraulic systems can be designed for low-force operation, which reduces operator fatigue.

Choosing a machine with these safety features means you are investing in both productivity and the well-being of your team.

When I choose a big piece of equipment, I always look beyond the machine itself. I think about the company behind it. A good manufacturer offers more than just a product; they offer peace of mind.

I always check a manufacturer's history. Companies with a long track record usually build reliable machines. For example, Trumpf, a German company founded in 1923, is known for its cutting-edge technology and precision. Piranha, an American company from 1985, also has a strong reputation for its punching machines. I also see companies like Hydraulic Solutions Inc. and PunchMaster offering robust and specialized options. Their experience means they understand what I need.

A solid warranty is a must-have for me. Manufacturers typically offer a warranty that starts on the purchase date. If the machine has a defect during this time, they will repair or replace it without charge. I always contact customer service for specific repair details. It's good to know that while implied warranties are usually limited to the explicit warranty period, state laws can sometimes change these rules.

I value strong technical support. Good manufacturers offer on-site installation and guidance. They make sure the machine runs normally. They also provide detailed technical training for my operators. This training covers everything from how the machine works to maintenance and safety. Sometimes, they even design custom courses based on my specific needs. I find this support invaluable.

The support doesn't stop after I buy the machine. I look for companies that offer whole-process follow-up service. They might even visit me regularly to get my feedback. They also provide wearing components at good prices and deliver them fast. For major issues, I appreciate remote diagnostic systems and effective technical support. Maintenance contracts can also help keep my machine in top shape.

Choosing the right manufacturer is just as important as choosing the right machine. I always prioritize companies with a strong track record, clear warranties, excellent technical support, and reliable after-sales service. This ensures my investment is protected and my operations run smoothly for years to come.

When I consider a new machine, I always look at the money side of things. It's not just about the sticker price; it's about the long-term value.

The first thing I think about is the upfront cost. This is the price tag you see. It's a big number, but it's only part of the story. I know I need to balance this initial cost with what the machine can do for my business.

I also look at the "hidden costs" that add up over time. These include things like energy use, maintenance, and any downtime. On the flip side, I see how efficiency gains, like saving on labor and materials, can quickly pay me back. New technology, like energy-efficient drives, really helps lower these costs and boosts overall efficiency.

A new machine can really supercharge my output. I've seen how it streamlines workflows and reduces the physical effort needed. It allows for precise hole punching on thick metal sheets, which speeds up assembly. I can even do on-site customization, cutting down on downtime. Plus, better accuracy means I can handle more complex designs. AI and smart sensors help with real-time monitoring, which means less downtime and better overall performance.

I want my investment to last. The machine's frame design and the quality of its hydraulic system really matter for its lifespan. Good after-sales support and thinking about future power needs also help keep its value high. I know that regular maintenance can extend a machine's life by 30% to 50%. The environment where it operates, like temperature and humidity, also plays a role in how long it lasts.

This section helps me understand the full financial picture, from buying the machine to how much value it brings over time.

I hope this checklist helps you! Remember, a comprehensive evaluation is key. Always align your hydraulic punching machine choice with your specific business goals. For unique needs, I always recommend seeking expert advice. This ensures you make the best investment for your operations.

The hydraulic machines offer immense power and precision. They handle thick materials easily. This means I can get the consistent, high-quality holes every time.

I always match tonnage to my material's thickness and type. The thicker steel needs more force.

I focus on daily cleaning and weekly lubrication. Checking hydraulic fluid levels and filters monthly is also crucial. This keeps my machine running smoothly.

This FAQ section addresses some common questions I hear about hydraulic punching machines, covering their main benefits, how to select tonnage, and essential maintenance.